Maximizing Efficiency with Superheated Steam: How Superheaters Boost Heat Transfer and Cut Fuel Costs

The general purpose of steam in industry is to convert fuel energy to heat energy and transport that heat energy safely and efficiently from a boiler to a distant point where the heat is used for a specific purpose.

The purpose of a superheater in a boiler is to increase the heat energy of the steam by raising the temperature of the steam that exits the boiler while maintaining the same pressure. For a given steam pressure, the temperature of the water and steam will be the same inside the boiler. By superheating the steam, more heat energy can be transmitted in the same mass(lbs) of steam. This means that less water has to be boiled to transfer the same amount of heat from the boiler to the end use equipment. As an example, for 150 psi steam superheated to 650°F, 12.9% less water has to be boiled to transmit the same amount of heat energy in the steam. This is an immediate consequential savings of utilizing superheat.

The greater saving is achieved in the exponentially increased rate of heat transfer based on higher heat differentials.

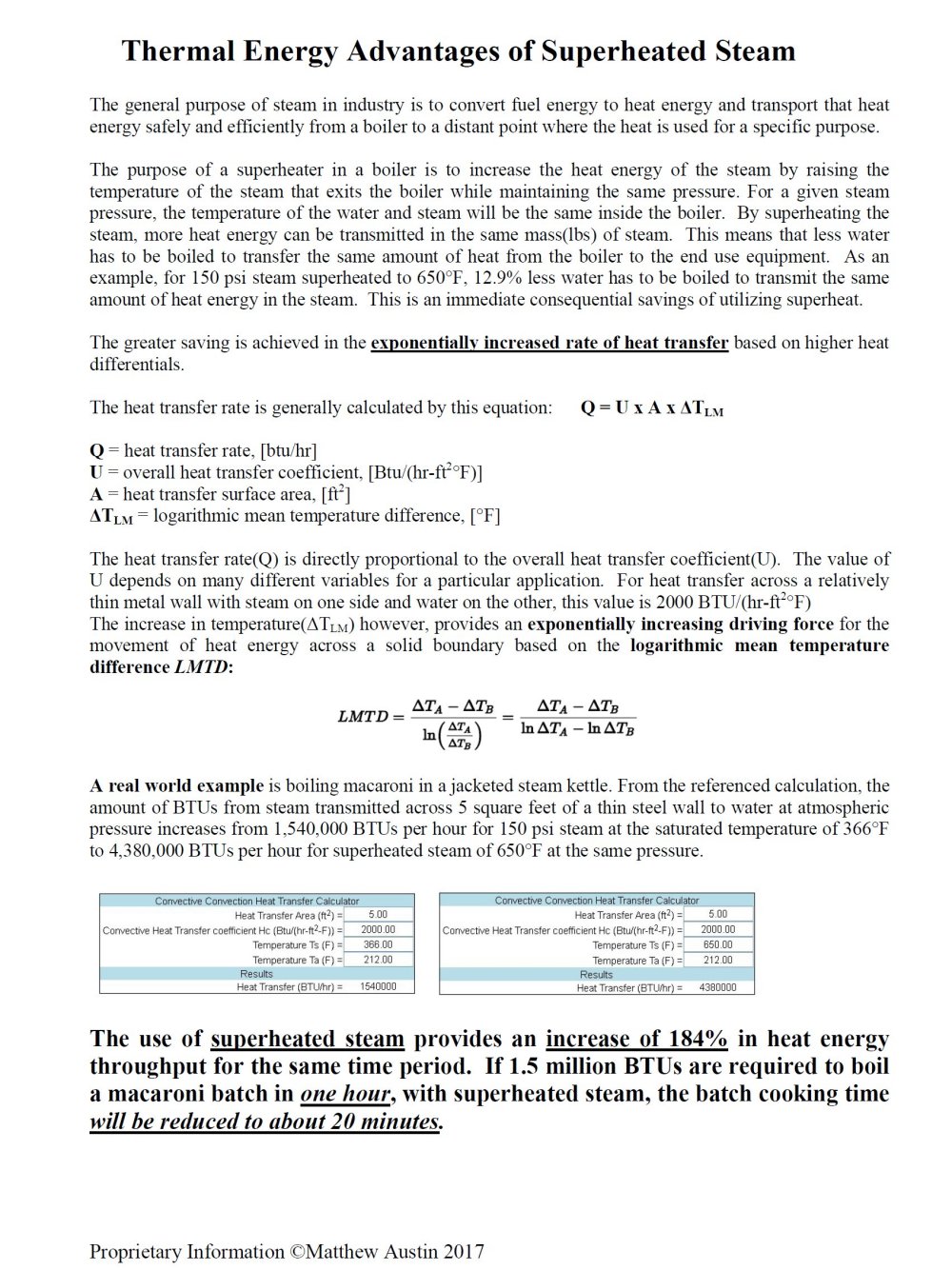

The heat transfer rate is generally calculated by this equation:

Q = U x A x ΔTLM

The Power of ΔT: How Superheat and Surface Area Drive Exponential Heat Transfer

Q = heat transfer rate, [btu/hr] U = overall heat transfer coefficient, [Btu/(hr-ft2°F)]

A = heat transfer surface area, [ft2] ΔTLM = logarithmic mean temperature difference, [°F]

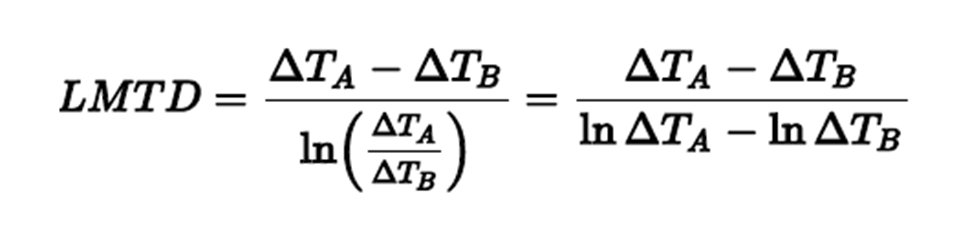

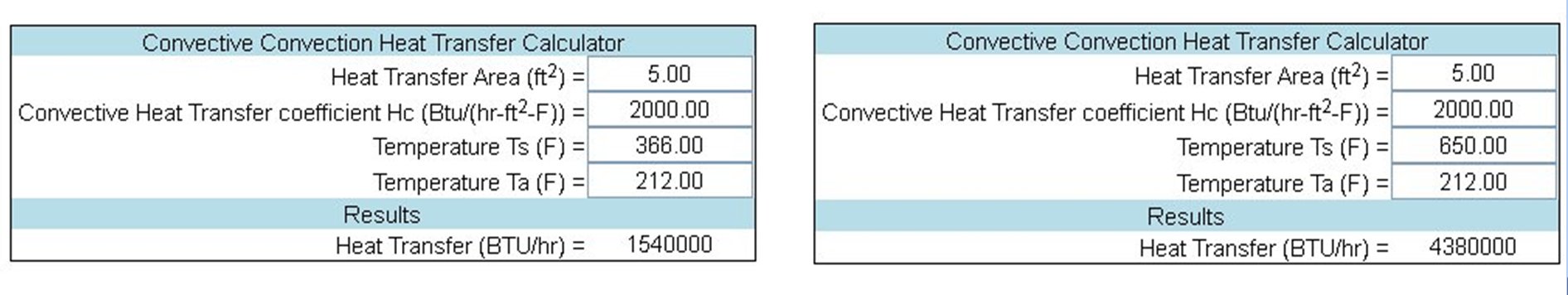

The heat transfer rate(Q) is directly proportional to the overall heat transfer coefficient(U). The value of U depends on many different variables for a particular application. For heat transfer across a relatively thin metal wall with steam on one side and water on the other, this value is 2000 BTU/(hr-ft2°F)

The increase in temperature(ΔTLM) however, provides an exponentially increasing driving force for the movement of heat energy across a solid boundary based on the logarithmic mean temperature difference LMTD:

A real world example is boiling macaroni in a jacketed steam kettle. From the referenced calculation, the amount of BTUs from steam transmitted across 5 square feet of a thin steel wall to water at atmospheric pressure increases from 1,540,000 BTUs per hour for 150 psi steam at the saturated temperature of 366°F to 4,380,000 BTUs per hour for superheated steam of 650°F at the same pressure.

The use of superheated steam provides an increase of 184% in heat energy throughput for the same time period. If 1.5 million BTUs are required to boil a macaroni batch in one hour, with superheated steam, the batch cooking time will be reduced to about 20 minutes.

Industrial Gains with Superheated Steam:

Faster Processes, Greater Efficiency, and Scalable Power Generation

The general purpose of steam in industry is to convert fuel energy to heat energy and transport that heat energy safely and efficiently from a boiler to a distant point where the heat is used for a specific purpose. The purpose of a superheater in a boiler is to increase the heat energy of the steam by raising the temperature of the steam that exits the boiler while maintaining the same pressure. Superheating steam can only occur if the steam is passed out of the boiler and into separate piping components where additional heat energy is provided to be absorbed by the steam. By superheating the steam, more heat energy can be transmitted in the same mass(lbs) of steam. This means that less water has to be boiled to transfer the same amount of heat from the boiler to the end use equipment. As an example, for 150 psi steam superheated to 650°F, 12.9% less water has to be boiled to transmit the same amount of heat energy in the steam.

Heat flow across a boundary is not just faster with a higher heat differential, but exponentially faster. In industrial processes, such as cooking, laundry drying, chemical processing, etc., using superheated steam heat can provide measurably shorter process times. It still takes the same number of BTUs to complete the process, but 10%, 20% or 30% less time manifests savings in many ways.

A major supplier of industrial laundry drying and ironing equipment provides a line of flatwork ironers designed for use of saturated steam at 150 psi or thermal fluid oil operating at 650°F. Use of the 650°F thermal oil allows the advertised throughput capacity to be increased by 50%.

Boiler and generator output can be scaled to suit the factory size. Integral superheaters installed in a firetube boiler makes a practical application of electrical generation as a value added process between the boiler room and the process plant. A 350 psi superheated firetube boiler feeding a steam turbine electric generator will exhaust process steam at 100 psi at 570°F.

Product Quality Index

Energy Generation

OFFICE LINE

1.800.555.6789

EMERGENCY

1.800.555.0000

WORKING HOURS